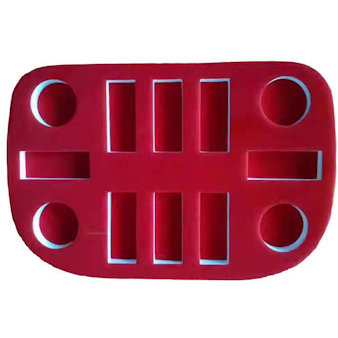

Custom Foam Insert

We provide a range of custom foam inserts for your equipment protection.

Custom Cutout for EVA Foam Insert

Custom cutout foam keeps your item neat and tidy on your hard case. Cost-effective for high-volume production.

Need a custom-fitting foam insert for storing odd-shaped items.

Send us a photo of your items and layout, and we will guide you with a few simple steps to have your foam made.

One-time engineering fee starts from $300 onwards. Foam per piece starts from $30-50 onwards depending on the size and quantity.

Contact us for the actual price.

EVA foam hardness can range from 18 to 90 degree. Common standard hardness are

- 18 degree

- 25 degree

- 38 degree (most common)

- 45 degree

- 50 degree

- 60 degree

- 70 degree

- 80 degree

- 90 degree

Material available for custom foam cut-out

- PU Sponge (Polyurethane)

- PE Foam (Polyethylene)

- EPE (Expanded Polyethylene)

- EVA (Ethylene Vinyl Acetate)

Click here to check out and compare other types of packaging material.

Reference

- My Case Builder (custom foam-making service)

- NShot Pro (Software digitizes object items to digital CAD drawing)

Custom Cutout for Closed Cell Polyethylene Foam

Closed Cell Polyethylene (CCPE) Foam Inserts

Closed Cell Polyethylene Foam (CCPE) inserts offer premium protection, precise customization, and eco-friendly durability. Their closed-cell structure provides exceptional resistance to impact, moisture, and chemicals, keeping your products safe during transit. Custom-cut to fit your product dimensions, CCPE inserts maximize space efficiency while enhancing presentation for a wide range of industries.

Key Material Features:

- Material: Cross-linked polyethylene (XLPE/XPE)

- Structure: Closed-cell foam (water- and moisture-resistant), ideal for seals and gaskets

- Density: Nominal ~29 kg/m³ (LD29)

- Surface & Feel: Firm, slightly textured, premium appearance; more rigid and lightweight than EVA foam

Performance Highlights:

- Lightweight yet dimensionally stable

- Excellent shock absorption

- Good recovery after compression

- Easy to cut and machine

- Commonly used for protective equipment inserts

Popular CCPE Foam Brands & Grades:

- Plastazote® (LD29) – Lightweight, firm, closed-cell polyethylene foam with excellent chemical resistance

- Other LD grades: LD15, LD18, LD24, LD29, LD33, LD45, LD60, LD70

- HD grades: HD30, HD60, HD80, HD115

- Optional features: flame retardant, ESD/antistatic, or conductive

Typical Applications:

- Protective packaging and equipment cases

- Industrial cushioning and sports padding

- Medical device protection

Alternative Foam Options

🔵 Evazote®

- Material: Cross-linked ethylene-vinyl acetate (EVA) foam

- Characteristics: Softer and more resilient than Plastazote®, excellent impact absorption, rubber-like feel

- Use Cases: Sports/leisure products, vibration damping, flexible protective inserts

🟡 Supazote®

- Material: Cross-linked ethyl-methyl acrylate (EMA) foam

- Characteristics: Soft to very soft, gentle cushioning

- Use Cases: Soft-touch interfaces, orthopedic products, comfort-focused padding

Quick Comparison:

| Foam Type | Firmness | Key Benefit | Typical Use |

|---|---|---|---|

| Plastazote® | Firm → Very Firm | Rigid, protective cushioning | Equipment inserts, industrial packaging |

| Evazote® | Mid → Soft | Flexible, resilient padding | Sports, vibration damping, flexible inserts |

| Supazote® | Soft → Very Soft | Comfort-oriented cushioning | Orthopedic & soft-touch applications |

Other Custom Foam Manufacturers

Click here for other custom foam manufacturers in Singapore.

-> Click here to return to the range of protective foams available from Rugged-Box.com.